If your ice cream machine isn’t working right, start by checking the power and control panel to guarantee everything is set correctly and there are no error signals. Inspect the refrigeration system for frost buildup or refrigerant leaks, and make sure the compressor and motor are running smoothly. Clean and lubricate moving parts like the auger and paddle, and verify water connections are secure and leak-free. For more tips to troubleshoot and fix common issues, keep going to uncover detailed steps.

Key Takeaways

- Check power connections, control panel settings, and reset buttons to resolve startup issues.

- Inspect refrigeration components and defrost coils to prevent freezing problems and ensure proper cooling.

- Clean filters, lubricate moving parts, and verify mechanical components for smooth operation and leak prevention.

- Ensure water connections are secure, hoses are intact, and no leaks are present in water supply lines.

- Perform a proper power cycle, clear machine memory, and follow maintenance routines to fix glitches and maintain performance.

Checking the Power and Basic Settings

Before troubleshooting your ice cream machine, make sure it’s properly powered on. Check the power supply to verify it’s securely plugged in and the outlet is functioning. Sometimes, a simple power outage or loose cord can cause issues. Next, examine the user interface—look for any error messages or blinking lights that indicate a problem. Make sure the control panel is set correctly and that the machine is turned on. If there’s a power switch, toggle it to confirm it’s in the “on” position. Reset any buttons if needed. Confirm the voltage matches your machine’s requirements. Ensuring a steady power supply and correct settings on the user interface is an essential first step before proceeding to more detailed inspections. Additionally, display clarity and color accuracy in your machine’s display can affect how well you interpret error codes or alerts, so ensure the display is showing clear and accurate information. Checking the fuse or circuit breaker can also help identify if electrical issues are preventing your machine from operating properly. Performing a visual inspection of electrical components can reveal loose connections or damaged wires. For optimal performance, verify that the power cord is not damaged and that your power source provides consistent voltage.

Inspecting the Freezing Components

To guarantee your ice cream machine freezes properly, you should carefully inspect the freezing components. Start by checking for frost buildup on the evaporator coils; excessive frost can hinder heat transfer and reduce freezing efficiency. If you notice thick frost, defrost the unit completely before proceeding. Next, verify the refrigerant levels—low refrigerant can cause inadequate freezing. If levels are low, you might see reduced ice production or inconsistent texture. Keep an eye out for leaks or damage to refrigerant lines, as these issues can lead to refrigerant loss. Regular inspection of these components helps ensure your machine maintains the proper cold temperatures needed for perfect ice cream. Addressing frost buildup and refrigerant issues promptly can prevent more severe problems down the line. Additionally, maintaining proper air purifier maintenance and care can help prevent dust and debris from affecting your machine’s cooling system. Ensuring good air quality around your appliance can also support its efficient operation. Proper Mazda Tuning techniques, such as checking for refrigerant leaks, can be applied to maintain optimal cooling performance. Regularly inspecting the surrounding environment for dust accumulation can further enhance the cooling efficiency of your ice cream machine. Being aware of Kia Tuning practices related to cooling systems can also provide insights into maintaining frost-free operation.

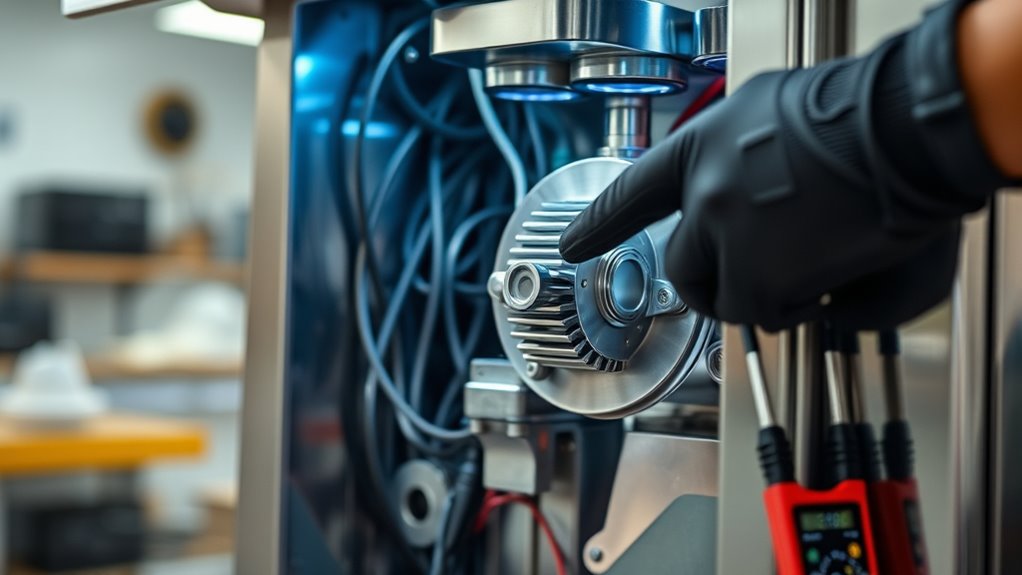

Troubleshooting the Compressor and Motor

- Verify the compressor is running smoothly without excessive noise or vibration.

- Inspect the motor winding for visible damage or burns.

- Ensure the compressor’s electrical connections are secure and free of corrosion.

- Regularly check and clean the filters to maintain optimal performance and prevent issues that could affect the compressor and motor.

- Additionally, inspecting the cooling system helps prevent overheating and prolongs the lifespan of the compressor and motor.

- Remember that airless paint sprayer maintenance, including proper lubrication and part replacement, can also contribute to smoother operation and fewer malfunctions.

- To maintain the efficiency of the compressor and motor, consider wire integrity and connections, as loose or damaged wires can lead to operational issues.

- Consulting Gold IRA rollovers and related investment strategies can provide insights into diversifying your assets to protect against economic fluctuations that might otherwise impact your equipment maintenance budget.

Clearing Clogs and Ensuring Proper Lubrication

Have you noticed your ice cream machine isn’t cooling properly or making unusual noises? Mucus buildup can clog internal parts, hindering performance. To fix this, carefully clear any obstructions and check for buildup in the coolant passages. Proper lubricant application is essential; it reduces friction and prevents parts from seizing. Use the right lubricant, and apply it sparingly to moving components like the auger and gears. Here’s a quick guide:

| Step | Details |

|---|---|

| Clearing mucus buildup | Use a soft brush or compressed air to remove deposits. Regular cleaning prevents clog formation. |

| Applying lubricant | Use food-grade lubricant, sparingly on moving parts. Proper lubrication reduces wear and prolongs equipment life. |

| Checking for clogs | Inspect coolant and lubricant pathways for blockages. Ensuring clear pathways maintains optimal performance. |

Regular cleaning and lubrication keep your machine running smoothly. Additionally, understanding the self-watering system can help in maintaining the overall health of your equipment by preventing moisture-related issues.

Examining the Mixing Paddle and Auger

Since the mixing paddle and auger are crucial for smooth ice cream production, inspecting them regularly is essential. You want to confirm they aren’t worn, damaged, or jammed, which can cause inconsistent texture or machine failure. During auger inspection, look for cracks, bent parts, or buildup that could hinder operation. For the mixing paddle, check for cracks, warping, or signs of wear that might affect mixing efficiency. Regular cleaning and proper lubrication can also prevent air leaks and ensure consistent performance. Additionally, understanding candles can help you troubleshoot and optimize your machine’s operation in a busy environment. Remember:

Regularly inspect the mixing paddle and auger for cracks, warping, buildup, or damage to ensure optimal ice cream quality.

- Worn or damaged parts reduce ice cream quality

- Buildup can cause jams or overheating

- Proper alignment ensures even mixing and prevents strain

Regularly examining the mixing paddle and auger helps you catch issues early, keeping your machine running smoothly and producing perfect ice cream every time.

Addressing Leaks and Water Dripping Issues

Start by inspecting your water connections to spot any leaks or loose fittings. Tighten any fittings that seem loose, and check seals for signs of wear or damage. Replacing worn seals can often stop drips and prevent future leaks. Additionally, ensuring that all connections have adequate sealing and proper fit can improve the overall performance of your ice cream machine. Recognizing the importance of cultural practices in maintaining equipment can also provide valuable insights into effective troubleshooting.

Inspect Water Connections

Inspecting water connections is a critical step in troubleshooting leaks and water dripping issues in your ice cream machine. You need to check for proper water flow and guarantee the connection integrity is solid. Leaks often happen when fittings are loose or damaged, causing water to escape. Carefully examine all hoses and fittings for cracks, corrosion, or signs of wear.

- Confirm all connections are tight and secure

- Look for any visible cracks or damage in hoses

- Ensure water flow is steady and unobstructed

Addressing these points helps prevent leaks and maintains ideal operation. Properly secured and intact connections keep water where it belongs, reducing drips and potential damage. Regular inspection of water connections is essential for long-term machine reliability.

Tighten Loose Fittings

Loose fittings are a common cause of leaks and water drips in your ice cream machine. To fix this, start by inspecting all hoses and connections. Tighten any loose fittings carefully, but avoid overtightening, which can damage parts. If you notice a gasket that’s worn or damaged, gasket replacement is essential to stop leaks. Check the hoses for cracks or bulges, and replace them if necessary. When tightening, focus on hose clamps or fittings that secure water lines, ensuring they are snug but not overly tight. Proper hose tightening prevents water from escaping and keeps your machine working efficiently. Regularly inspecting and maintaining these fittings can save you from bigger issues down the line and keep your ice cream machine running smoothly.

Replace Worn Seals

Worn seals are a common culprit behind leaks and water drips in your ice cream machine. When you notice leaks, seal replacement is often necessary to restore proper function. Over time, gaskets can become brittle or cracked, compromising the seal’s integrity. To fix this, carefully remove the old gasket and replace it with a new one designed for your machine. Proper gasket repair prevents water from escaping and helps maintain the right temperature. Keep in mind:

- Regular inspection of seals can catch damage early

- Using the correct seal type ensures a snug fit

- Proper installation is key to preventing future leaks

Resetting the Machine and Performing a Hard Restart

To reset your ice cream machine, start by powering it off completely and unplugging it for a few minutes. Then, plug it back in and turn it on to verify a proper power cycle. This process helps clear the machine’s memory and can resolve many common issues.

Power Cycle Properly

Have you tried resetting your ice cream machine to resolve ongoing issues? Performing a proper power cycle is essential for a successful machine reset. To do this, unplug the machine from the power source, wait at least 60 seconds, then plug it back in. This hard restart clears temporary glitches and resets internal systems.

Remember these key points:

- *Ensure the machine is completely powered off before restarting*

- *Wait the full 60 seconds to allow internal components to reset*

- *Avoid rushing the process, as a proper power cycle ensures a thorough machine reset*

This simple step can often resolve minor malfunctions and get your ice cream machine working smoothly again. Proper power cycling is a quick fix that can save you time and frustration.

Clear Machine Memory

After successfully powering down your ice cream machine, it’s often helpful to clear its machine memory to resolve lingering issues. Clearing the memory resets any temporary glitches that might be affecting performance. To do this, disconnect the machine from power and wait for about 30 seconds. Some models require a specific combination of button presses during startup to perform a hard restart, which clears the memory. This step is especially important if you’ve recently installed software updates, as outdated or incomplete updates can cause malfunctions. Performing a hard restart ensures the machine loads the latest software properly. Once you’ve completed this process, power the machine back on and check if the issues are resolved. Clearing the machine memory can often improve overall functionality and prevent future problems.

Maintaining Your Ice Cream Machine for Long-Term Performance

Regular maintenance is essential to keep your ice cream machine running smoothly and guarantee it produces high-quality frozen treats over time. Consistently following cleaning routines prevents residue buildup and contamination, ensuring peak performance. Focus on ingredient quality, as fresh, high-grade ingredients improve taste and reduce machine strain. To maintain your machine’s long-term performance, remember:

- Regularly clean all parts to prevent mold and bacteria growth

- Check and replace worn seals and gaskets for proper sealing

- Use high-quality ingredients to minimize residue and machine wear

Frequently Asked Questions

How Often Should I Clean and Sanitize My Ice Cream Machine?

You should follow a strict cleaning schedule to keep your ice cream machine in top shape. Typically, clean and sanitize your machine after every use or at least daily if used continuously. Incorporate sanitization tips like using proper cleaning agents and ensuring all parts are thoroughly dried. Regular cleaning prevents bacteria buildup and ensures ice cream quality, so stay consistent with your cleaning routine for the best results.

What Are Common Signs of a Faulty Compressor?

Imagine a quiet hum turning into a loud, grinding noise—that’s your compressor signaling trouble. You might notice unusual compressor noise or overheating issues, which indicate a faulty compressor. These signs suggest it’s struggling to cool effectively, risking more serious damage. When you hear persistent noise or feel excessive heat, it’s time to check the compressor. Addressing these symptoms promptly can prevent costly repairs and keep your machine running smoothly.

Can Improper Ingredients Cause Machine Malfunctions?

Improper ingredients can definitely cause machine malfunctions. Poor ingredient quality or incorrect mixtures can lead to inconsistent mixture consistency, which strains the machine’s components. When your ingredients aren’t up to standard, the machine has to work harder to process them, increasing the risk of breakdowns or operational issues. Make sure to use high-quality ingredients and maintain proper mixture consistency to keep your ice cream machine running smoothly.

How Do I Troubleshoot Uneven Freezing or Inconsistent Texture?

You might notice texture issues or freezing problems when your ice cream isn’t coming out right. Coincidentally, uneven freezing often stems from temperature inconsistencies or overloading the machine. To troubleshoot, make certain the freezer is at the right temperature, don’t overload the machine, and check for proper airflow. Sometimes, minor adjustments can fix the problem, restoring smooth, creamy consistency and preventing future freezing issues.

What Safety Precautions Should I Take When Repairing the Machine?

When repairing the machine, you should prioritize electrical safety by unplugging it before starting. Wear protective gear like gloves and safety glasses to prevent injuries from sharp parts or accidental splashes. Make sure the area is dry to avoid electrical shocks, and follow the manufacturer’s instructions carefully. If you’re unsure, consult a professional. Taking these precautions keeps you safe while fixing the machine.

Conclusion

Think of your ice cream machine like a trusty car—you rely on it to run smoothly, but sometimes it needs a quick tune-up. Just like a mechanic checks the engine, you can troubleshoot simple issues to keep your machine churning out delicious treats. With these easy steps, you’ll prevent small problems from turning into costly repairs. Keep your machine in top shape, and you’ll be enjoying perfectly creamy ice cream all season long—no breakdowns, just sweet success.