If your ice cream machine suddenly stops working, first check that it’s plugged in and the outlet is functioning. Verify the temperature settings and adjust if needed, making sure sensors are clean. Inspect the compressor and condenser for dirt or damage, and clear any blockages in lines or vents. Reset or restart the machine, and ensure refrigerant levels are proper. If issues persist, professional help may be necessary—keep going to learn how to handle more complex problems effectively.

Key Takeaways

- Unplug the machine immediately to prevent further damage and ensure safety.

- Check for visible issues like leaks, blockages, or unusual noises and address if possible.

- Verify power supply and reset the machine after a few minutes if no obvious problem is found.

- Confirm the temperature settings are correct and monitor for rapid temperature changes.

- Contact a professional technician promptly if the problem persists or involves refrigerant, leaks, or severe malfunctions.

Check the Power and Connections

Before troubleshooting your ice cream machine, you should first verify that it’s properly plugged in and receiving power. Power issues are a common cause of malfunction, often stemming from connection problems. Check that the power cord is securely connected to both the machine and the outlet. Inspect the outlet itself by testing it with another device to ensure it’s working correctly. If the machine still doesn’t turn on, try plugging it into a different outlet. Sometimes, a loose connection or a tripped circuit breaker can disrupt power. Avoid assuming the problem is internal; many times, resolving connection problems and confirming power supply fixes the issue quickly. Ensuring your machine is properly connected and powered up is the first critical step in emergency troubleshooting. Additionally, confirming the power supply quality can help prevent further issues. Also, verifying that the electrical connection is stable can prevent unexpected interruptions during operation. Regularly checking the electrical connections can help maintain consistent performance and avoid unexpected failures. To further prevent issues, consider inspecting the circuit breaker to ensure it hasn’t tripped unexpectedly, and inspecting the power cord for any signs of damage to ensure safety and proper function.

Examine the Temperature Settings

You should verify that the temperature is accurate to guarantee proper freezing. If the settings are off, adjust them according to the manufacturer’s guidelines. Proper temperature control is key to fixing the machine and preventing future issues. Additionally, monitoring grocery savings strategies can help anticipate maintenance needs before problems occur. Regularly checking the user manual can provide specific instructions tailored to your model and help resolve common temperature-related problems. For optimal performance, ensuring that the ECU tuning is correctly configured can also contribute to maintaining the right temperature and efficiency. Remember, maintaining consistent operating conditions is especially important in seasonal variations to prevent malfunctions.

Check Temperature Accuracy

Have you verified that the ice cream machine’s temperature settings are accurate? If not, start by checking the thermostat calibration. A miscalibrated thermostat can cause incorrect temperature readings, leading to product spoilage or inconsistency. Use a reliable thermometer to test the actual temperature inside the machine. If the readings don’t match the set temperature, you may have a sensor malfunction or calibration issue. Sensor malfunction can cause the machine to display false temperatures, so it’s vital to verify sensors are clean and functioning properly. Address any discrepancies immediately, as inaccurate temperature readings can jeopardize safety and quality. Confirming the accuracy of your temperature settings is a key step before proceeding to adjust or troubleshoot further. Additionally, inspecting temperature sensors for damage or dirt can help ensure proper operation. Ensuring proper thermostat calibration is essential for maintaining consistent product quality and safety. Regularly checking temperature accuracy and monitoring air quality in your workspace can prevent many common issues and keep your machine running smoothly.

Adjust Settings Accordingly

If the temperature readings are off or inconsistent, adjusting the machine’s settings is essential to guarantee proper operation. Proper temperature calibration ensures your ice cream freezes correctly and maintains quality. Start by consulting your user manual for specific instructions on setting adjustments. Make small changes and monitor the results carefully. Remember, precise calibration can prevent spoilage or over-freezing. Additionally, automation technologies in equipment can help maintain consistent temperature control, reducing manual errors and improving product quality. Regularly checking and maintaining your equipment’s temperature sensors can help detect issues early and keep your machine running smoothly. Incorporating routine preventive maintenance can further enhance accuracy and extend the lifespan of your equipment. Utilizing advanced diagnostic tools can assist in identifying calibration issues more efficiently. Taking the time to fine-tune your settings shows you care about quality. Adjusting the temperature carefully is the key to avoiding emergency breakdowns and ensuring your machine runs smoothly. Properly managing environmental conditions around your equipment can also contribute to consistent performance and prevent temperature fluctuations.

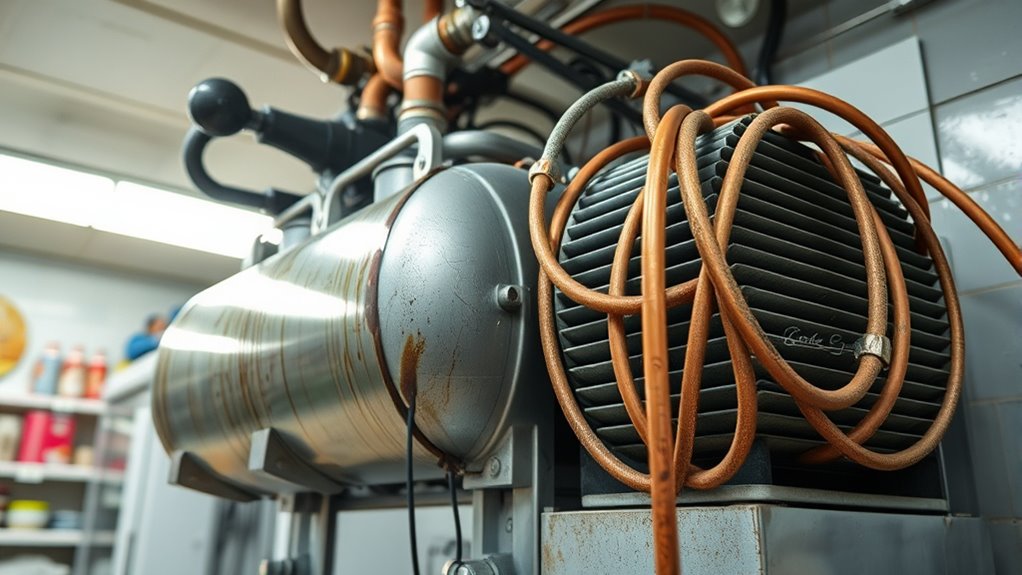

Inspect the Compressor and Condenser

To guarantee the ice cream machine’s compressor and condenser are functioning properly, start by visually inspecting them for signs of damage, dirt, or debris. Look for bent or broken fins on the condenser and ensure the compressor is free of oil leaks or corrosion. Dirty condensers hinder heat exchange, so perform condenser cleaning if you notice buildup or dirt. Proper airflow is vital, so clear any obstructions around the unit. For compressor troubleshooting, listen for unusual noises or vibrations that might indicate a problem. Regular inspection helps prevent overheating and ensures efficient operation. If you spot dirt or damage, address it immediately to maintain optimal cooling. Properly maintained compressors and condensers are key to avoiding costly repairs and keeping your ice cream machine running smoothly. Additionally, understanding cookie management and user privacy preferences can help ensure your equipment’s online support tools function properly, aiding in diagnostics and maintenance. Maintaining component integrity is essential for consistent performance, and being familiar with preventive maintenance practices can extend the lifespan of your machine. Incorporating regular diagnostic checks based on manufacturer guidelines can further prevent unexpected failures and improve overall reliability. Recognizing signs of failure early can also help prevent complete breakdowns and costly repairs.

Reset or Restart the Machine

When your ice cream machine isn’t operating properly, resetting or restarting it can often resolve minor issues. It’s a simple step that can quickly restore functionality and reduce downtime. Before doing so, verify your cleaning schedule is up-to-date, as buildup can cause errors. Restarting the machine can also help address customer complaints about inconsistent texture or temperature.

Here are key tips:

- Turn off the machine completely and unplug it for a few minutes

- Check for any error messages or blinking lights

- Clear out any temporary glitches by restarting

- Regularly follow your cleaning schedule to prevent issues

A quick reset can save you time and effort, helping you serve perfect ice cream and keep customers happy.

Clear Any Blockages or Clogs

Blockages or clogs can substantially hinder your ice cream machine’s performance, causing uneven texture, slow operation, or complete shutdown. To fix this, start with blockage removal by carefully inspecting the feed and discharge lines. Look for any debris, ice buildup, or hardened mixture that might be obstructing flow. Use a soft brush or compressed air to clear out small clogs gently. For stubborn blockages, you may need to disassemble certain parts, but always follow the manufacturer’s instructions. Clog clearing is essential to restore proper circulation and prevent further damage. Ensure all pathways are clear before restarting the machine. Regularly checking for potential obstructions will help keep your ice cream machine running smoothly and prevent emergency breakdowns.

Verify the Refrigerant Levels

If your ice cream machine isn’t cooling properly or is running inefficiently, verifying the refrigerant levels is a crucial step. Low refrigerant can cause poor cooling, while refrigerant leaks compromise the system further. Ensure you perform level calibration to confirm the refrigerant amount is correct.

Check for signs of refrigerant leaks like oily spots or hissing sounds. Avoid guessing—accurate level calibration is key to proper function. If refrigerant levels are too low, the machine won’t cool effectively, risking spoilage and loss. Take these steps seriously to prevent costly repairs or downtime. Your quick action can restore cooling efficiency and keep your operation running smoothly.

- Feel the urgency of a machine that won’t chill

- Spot leaks before they worsen

- Trust your calibration skills

- Protect your business from costly failures

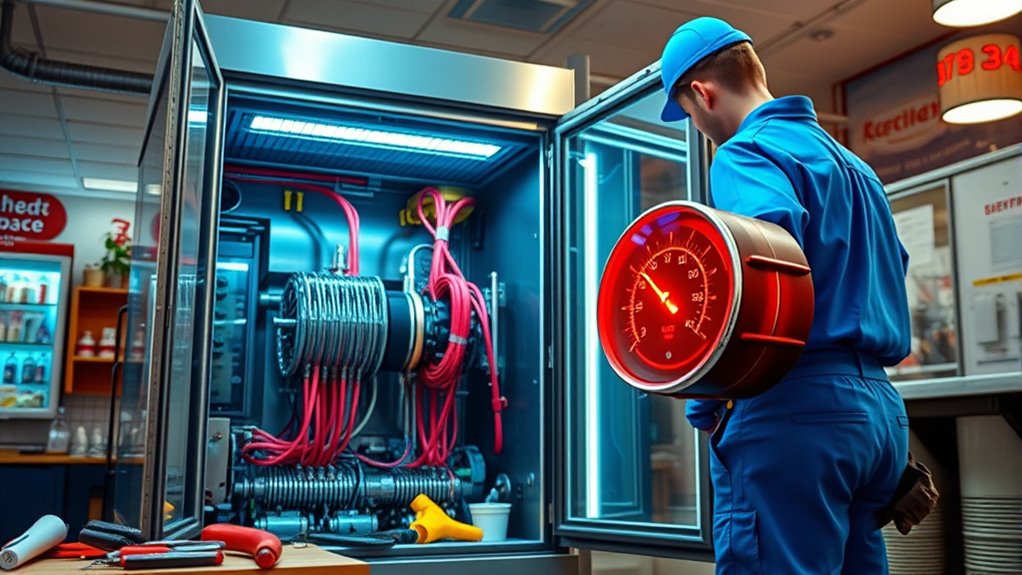

Contact Professional Service if Needed

Sometimes, despite your best efforts, troubleshooting and repairs fall outside your expertise. If your ice cream machine isn’t functioning properly despite basic checks, it’s time to contact professional service. Skilled technicians can perform thorough maintenance and handle emergency repairs safely and efficiently. Ignoring complex issues can worsen the problem or risk damage. When calling for help, ensure the technician specializes in ice cream machine repair. Here’s a quick guide:

| Issue Type | Recommended Action | Priority |

|---|---|---|

| Refrigeration failure | Seek professional maintenance | High |

| Unusual noises | Contact emergency repair team | High |

| Mechanical jams | Schedule professional help | Medium |

| Temperature inconsistencies | Call for expert diagnosis | High |

Prompt professional intervention saves time, money, and prevents further damage.

Frequently Asked Questions

How Often Should I Perform Maintenance on My Ice Cream Machine?

You should perform maintenance on your ice cream machine regularly to keep it running smoothly. Follow a cleaning schedule daily or after each use, and stick to your maintenance checklist, which includes inspecting parts, lubricating components, and checking for wear. Consistent upkeep prevents breakdowns and guarantees quality. Don’t wait for problems—make maintenance a routine, so your machine stays efficient and your customers stay happy.

What Safe Methods Exist for Cleaning Internal Components?

When cleaning internal components, you should follow strict cleaning protocols and sanitization procedures to guarantee safety. Use warm water and food-grade cleaning solutions, scrubbing all surfaces thoroughly. Rinse completely to remove any residue, then sanitize with approved sanitizers. Avoid harsh chemicals or abrasive tools that could damage parts. Regularly inspecting and maintaining your machine helps prevent contamination and ensures it operates smoothly and safely.

Are There Any Common Signs of Impending Failure?

You should watch for signs of impending failure like ice buildup inside the machine or strange noises during operation. Ice buildup indicates poor freezing or airflow issues, while strange noises could point to worn-out parts or motor problems. Address these symptoms promptly to prevent a breakdown. Regular maintenance and inspections help catch these signs early, ensuring your ice cream machine stays in good working order and avoids costly repairs or emergencies.

Can I Troubleshoot Electrical Issues Myself?

Did you know that 60% of appliance failures relate to electrical issues? You can troubleshoot electrical wiring yourself if you’re comfortable with basic tools and safety precautions. Start by turning off power and consulting troubleshooting guides specific to your machine. Check for loose connections or blown fuses. However, if you’re unsure or uncomfortable, it’s best to call a professional to avoid potential hazards.

What Warranty Options Cover Emergency Repairs?

You should check your warranty coverage to see if it includes emergency repair options. Many warranties offer roadside or urgent repair services, which can save you time and money during urgent situations. Contact your provider promptly to understand what’s covered and how to access these emergency repairs. Knowing your warranty details guarantees you’re prepared to handle unexpected issues efficiently, minimizing downtime and preventing further damage.

Conclusion

If your ice cream machine acts up, don’t panic—remember, even the best machines can have a hissy fit now and then. Check the power, settings, and filters first; a little troubleshooting can go a long way. If you’re still stuck, calling a professional is your best bet, just like calling a tech whiz from the olden days. With these steps, you’ll have your machine running smoother than a vintage ice cream parlor in no time.