To keep your ice cream business running smoothly, regularly replace key parts like beaters, agitators, and gaskets to prevent downtime and guarantee quality. Check thermostats, sensors, drive belts, and gears to maintain consistent operation and product texture. Use food-grade hoses and proper electrical components to avoid contamination and malfunctions. Staying on top of these critical replacements safeguards your equipment and boosts profits—stick around to learn which parts make the biggest difference.

Key Takeaways

- Regular maintenance of belts, gears, and seals prevents breakdowns and extends machine lifespan.

- Replacing worn components like agitators and thermostats ensures consistent product quality.

- Proper cleaning and inspection of gaskets and seals prevent leaks and costly spoilage.

- Monitoring and calibrating temperature sensors maintains optimal ice cream texture and safety.

- Using food-grade hoses and high-quality electrical parts reduces contamination and operational failures.

The Importance of Replacement Beaters and Agitators

Replacement beaters and agitators are vital to keep your ice cream machine running smoothly. They guarantee consistent mixing, which is essential when offering a variety of ice cream flavor variations. As you plan your seasonal menu, maintaining ideal agitator performance helps you you can also benefit from understanding filter maintenance, which ensures the longevity of your machine’s components. Regularly replacing these components prevents downtime and preserves the machine’s effectiveness. When you keep your beaters and agitators in top shape, you can confidently introduce new flavors aligned with seasonal trends, attracting more customers. Investing in quality replacements ultimately supports your menu flexibility and keeps your business running smoothly year-round. Staying informed about the benefits of using paint sprayers and their proper maintenance can also inspire creative marketing strategies to attract more customers. Additionally, ensuring the proper functioning of all machine parts aligns with maintaining automation efficiency, which is crucial in the competitive food service industry. Proper upkeep of these components not only enhances product consistency but also reduces operational costs over time.

Keeping Your Machine Cool With Thermostats and Temperature Sensors

To keep your ice cream machine running smoothly, proper calibration of thermostats is essential. Regularly check and adjust sensors to guarantee accurate temperature readings. Proper maintenance of these components helps prevent spoilage and ensures consistent product quality. Additionally, monitoring the temperature control system can help optimize performance and extend the lifespan of your equipment. Studies indicate that optimal angles can significantly improve the efficiency of cooling systems and prevent uneven temperature distribution. Incorporating AI-driven solutions into maintenance routines may further enhance system reliability and predictive diagnostics. Leveraging automation in business intelligence can facilitate real-time monitoring and swift response to any temperature fluctuations, reducing downtime. Implementing preventative maintenance strategies, including routine inspections, can further reduce unexpected breakdowns and downtime.

Thermostat Calibration Tips

Proper thermostat calibration is vital to guarantee your ice cream machine maintains the perfect temperature. Accurate calibration ensures consistent ice cream texture, enhancing flavor combinations and customer satisfaction. To achieve this, regularly check the thermostat settings against a reliable thermometer. Adjust the calibration dial carefully, making small changes and testing each time. Keep in mind that ambient temperature fluctuations can affect readings, so recalibrate periodically. Properly calibrated thermostats also streamline customer service techniques, reducing complaints about melted or overly frozen ice cream. Consider these tips for precise calibration:

- Use a certified thermometer for accuracy

- Record calibration results for future reference

- Test the temperature at different times of day

- Avoid touching sensor areas during calibration

- Follow manufacturer instructions closely

- Regular maintenance of thermostats helps prevent calibration drift and ensures consistent performance

- Incorporating digital temperature sensors can improve calibration accuracy over traditional methods

- Ensuring your thermostat sensors are clean and functioning properly can further enhance calibration precision

With proper calibration, your machine stays consistent, boosting your business’s reputation.

Sensor Maintenance Practices

Are your temperature sensors and thermostats functioning correctly to keep your ice cream machine at the ideal chill? Proper sensor maintenance guarantees consistent cooling, which is essential for flavor customization and satisfying customer feedback. Regularly clean and inspect sensors to prevent buildup that could cause inaccurate readings. Calibrate thermostats periodically to maintain precise temperature control, avoiding ice cream texture issues. When sensors work properly, you can confidently offer diverse flavors without risking spoilage or texture inconsistencies. Staying informed about sensor performance can inspire innovative approaches to your business environment. Consistent equipment maintenance is key to avoiding costly breakdowns and ensuring quality. Regularly updating your ceiling fan knowledge can also provide insights into modern technology that might be adapted for better equipment monitoring. Monitoring temperature regulation closely helps prevent spoilage and maintain optimal product quality. Stay attentive to sensor performance, and address any malfunctions promptly. This proactive approach helps you deliver high-quality ice cream every time, boosting customer satisfaction and encouraging repeat business. Good sensor maintenance ultimately safeguards your equipment, enhances flavor options, and keeps your customers coming back for more.

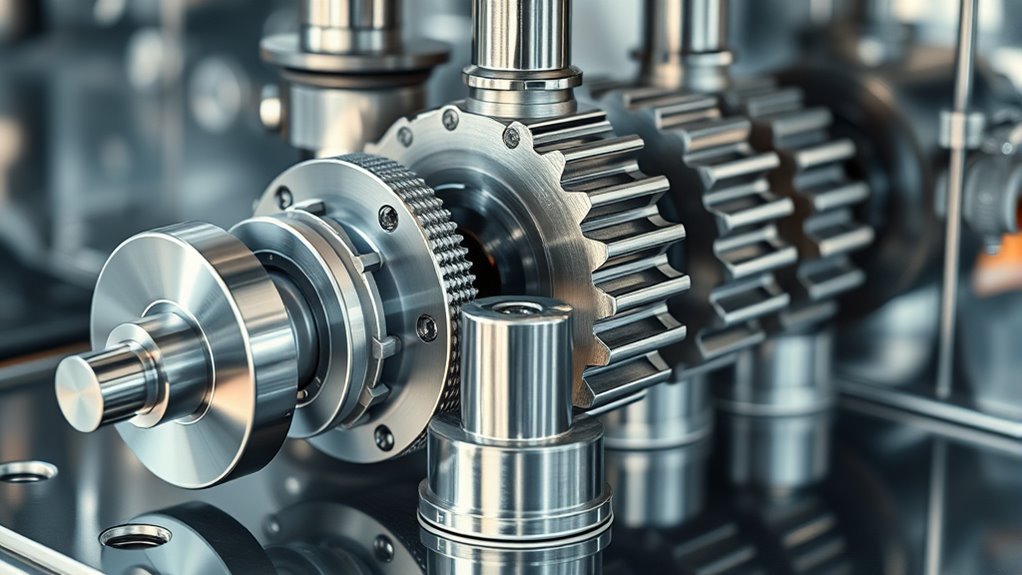

Ensuring Smooth Operation With Drive Belts and Gears

Ensuring smooth operation with drive belts and gears is essential for the reliable performance of your ice cream machine. Proper maintenance prevents downtime and ensures consistent product quality, which can support your ice cream flavor customization efforts and marketing strategies. Regularly check belt tension and alignment to avoid slippage or wear. Lubricate gears as recommended to reduce friction and noise. Keep an eye out for signs of wear or damage, replacing parts promptly. Consider these tips:

Regularly inspect and lubricate belts and gears to ensure ice cream machine reliability and consistent quality.

- Inspect belts for cracks or fraying

- Adjust tension to prevent slipping

- Lubricate gears to ensure smooth movement

- Replace worn or damaged belts and gears

- Keep components clean from debris

Maintaining these parts helps your machine run efficiently, giving customers the consistent experience they expect and enabling you to focus on marketing and flavor innovation. Regular inspections and proper care also contribute to overall equipment longevity, reducing costly repairs over time. Additionally, understanding the importance of sleep and mental health can improve your focus and decision-making, contributing to better maintenance routines. Proper tuning of your equipment might involve adjusting internal components for optimal performance, similar to how vehicle tuning enhances efficiency.

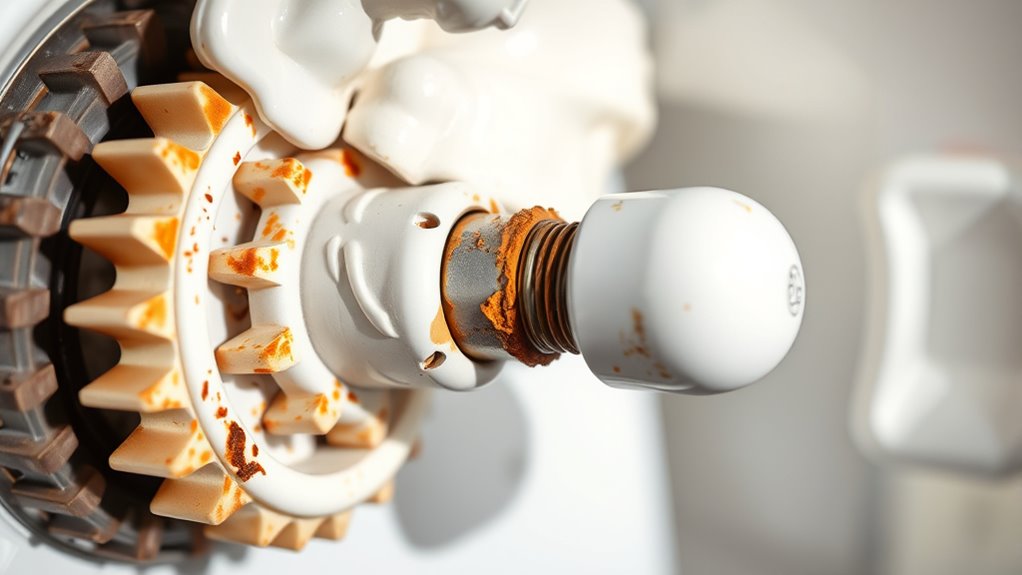

The Role of Gaskets and Seals in Preventing Leaks

Gaskets and seals are vital in maintaining the machine’s integrity by preventing leaks. You need to focus on seal integrity assurance and effective leak prevention strategies to keep your ice cream machine running smoothly. Choosing durable gasket materials ensures long-lasting performance and reliable protection. Regular inspection of signs of spoilage can help identify potential issues early and prevent costly repairs. Additionally, understanding resources and tools available for maintenance can enhance your ability to detect and address problems proactively. Incorporating lifecycle management practices can further extend the lifespan of your components and improve overall efficiency.

Seal Integrity Assurance

How do ice cream machines prevent messy leaks during operation? Seal integrity plays an essential role by maintaining a tight barrier between components. High-quality gaskets and seals prevent leaks that could spoil ice cream flavor customization options or disrupt marketing strategies. To ensure seal integrity, you should:

- Regularly inspect seals for cracks or wear

- Replace worn gaskets promptly

- Use compatible materials for specific fluids

- Tighten fittings to manufacturer specifications

- Keep seals clean and free of debris

These steps help keep the machine running smoothly, avoiding downtime and ensuring consistent product quality. Proper seal maintenance not only prevents leaks but also preserves the precise environment needed for flavor customization, ultimately supporting your business’s reputation and customer satisfaction.

Leak Prevention Strategies

Maintaining seal integrity is essential for preventing leaks that can compromise your ice cream machine’s performance. Proper gaskets and seals keep the refrigerant and mix contained, avoiding messy spills and costly repairs. When seals fail, leaks can lead to inconsistent ice cream texture and flavor options, impacting customer satisfaction. Ensuring tight seals also supports your branding strategies by maintaining a clean, professional appearance. Regular inspections and timely replacements of worn gaskets prevent leaks before they start. Using high-quality seals compatible with your machine’s materials guarantees durability and consistent operation. Remember, a well-maintained sealing system not only protects your equipment but also reinforces your commitment to quality, helping you keep customers happy with their favorite ice cream flavors and strong branding.

Gasket Material Durability

Choosing gaskets made from durable materials is essential because they directly impact your ice cream machine’s ability to prevent leaks. The gasket material must withstand constant exposure to moisture, temperature changes, and cleaning agents. Durability testing ensures the gasket maintains its seal over time, reducing the risk of failure. When selecting gasket material, consider factors like chemical resistance, compression set, and flexibility. Proper gasket durability means fewer replacements and less downtime.

- Resistance to extreme temperatures

- Chemical compatibility with cleaning agents

- Compression set resistance

- Flexibility for easy installation

- Long-term performance under repeated use

Maintaining Consistent Quality With Mix Pumps and Valves

To guarantee your ice cream maintains a consistent quality, it’s essential to properly manage mix pumps and valves. These components control the flow and proportion of ingredients, directly impacting flavor consistency. When mix pumps operate smoothly and valves are correctly calibrated, each batch maintains the same texture and taste, ensuring customer satisfaction. Regularly inspecting and cleaning these parts prevents blockages and leaks that could alter flavor profiles or cause uneven servings. Consistent pump and valve performance reduces the risk of over- or under-dispensing, keeping your product reliable. Proper maintenance also minimizes downtime, saving you money and protecting your reputation. In short, attentive care of your mix pumps and valves is vital for delivering high-quality ice cream every time, keeping customers happy and loyal.

The Significance of Food-Grade Hoses and Tubing

Why are food-grade hoses and tubing essential for your ice cream machine? They prevent contamination, ensuring food safety and maintaining high-quality standards. Using non-food-grade materials risks introducing harmful substances, which can compromise your product and damage your reputation. Proper hoses and tubing also help sustain consistent flow and prevent leaks, which is crucial for customer satisfaction.

Food-grade hoses prevent contamination, ensuring safety, quality, and customer satisfaction.

Key benefits include:

- Resistance to cleaning chemicals and frequent sterilization

- Avoidance of cross-contamination

- Durability under cold temperatures

- Flexibility for complex setups

- Compliance with food safety regulations

Choosing the right food-grade hoses and tubing guarantees your machine operates smoothly, keeps your products safe, and keeps customers coming back for more. It’s a small investment with a significant impact on your business’s success.

Troubleshooting Electrical Components: Fuses, Switches, and Motors

Ensuring your ice cream machine runs smoothly depends not only on using high-quality, food-safe hoses but also on maintaining its electrical components. If your machine isn’t freezing properly or stops unexpectedly, check the fuses, switches, and motors first. A blown fuse or faulty switch can disrupt power, affecting ice cream flavor variations and consistency. Testing motors with a multimeter helps identify if they’re functioning correctly. Incorporate customer feedback strategies by asking for input if issues persist, as repeated complaints about inconsistent texture may signal electrical problems. Regular troubleshooting keeps your machine running efficiently, prevents costly repairs, and maintains the quality your customers expect. Staying vigilant with electrical maintenance ensures your business continues to serve delicious ice cream without unexpected downtime.

When to Replace and How to Choose the Right Parts

Knowing when to replace parts on your ice cream machine is essential for maintaining peak performance and avoiding costly downtime. Regularly review your cleaning schedules, as neglected parts can wear faster. Proper staff training ensures everyone knows signs of wear or damage, like leaks or unusual noises. Substitute parts if you notice:

- Persistent operational issues despite cleaning

- Visible wear or corrosion

- Frequent breakdowns or errors

- Outdated or incompatible components

- Parts not responding after troubleshooting

Choosing the right parts involves verifying compatibility with your machine model and considering quality over price. Always buy from reputable suppliers. Proper maintenance, including timely replacements, prolongs machine lifespan and ensures consistent ice cream quality. Regular staff training helps identify issues early, preventing major failures.

Frequently Asked Questions

How Often Should Ice Cream Machine Parts Be Inspected for Wear?

You should inspect your ice cream machine parts regularly to guarantee peak performance. Follow a maintenance schedule that includes daily, weekly, and monthly checks, and create an inspection checklist to identify signs of wear or damage. Typically, you should inspect parts like the blades, seals, and motor components at least once a month. Prompt inspections help prevent breakdowns, maintain quality, and extend the lifespan of your equipment.

Can Replacing Parts Improve the Energy Efficiency of My Machine?

Did you know that replacing worn parts can boost your ice cream machine’s energy efficiency by up to 15%? By keeping your machine in top shape, you can achieve significant energy savings and reduce maintenance costs. Regularly upgrading parts guarantees your machine runs smoothly, consumes less power, and minimizes unexpected breakdowns. So, investing in quality replacements isn’t just about longevity—it’s a smart move for saving money and optimizing performance.

What Are Signs That a Part Needs Immediate Replacement?

If you notice signs of malfunction or troubleshooting indicators like unusual noises, inconsistent freezing, or leaks, it’s a clear sign a part needs immediate replacement. Pay attention to changes in performance, such as longer freezing times or difficulty dispensing ice cream. Addressing these issues promptly prevents further damage and keeps your machine running smoothly. Regularly inspecting your equipment helps catch problems early and guarantees peak operation.

Are There Compatible Aftermarket Parts Available for My Machine?

You might think finding compatible aftermarket parts is a hassle, but surprisingly, many options exist. These aftermarket options often promise better prices and availability, making it easier for you to keep your machine running smoothly. Just verify you check part compatibility carefully; not all aftermarket parts fit every model. Doing so saves you time and money, proving that sometimes, going aftermarket is the smart choice you didn’t know you needed.

How Can I Prevent Contamination During Part Replacement?

To prevent contamination during part replacement, you should strictly follow cleaning protocols and make certain your staff is well-trained. Make sure all parts and tools are thoroughly sanitized before handling. Train your team to follow proper hygiene procedures and use gloves when necessary. Regularly review and reinforce these practices, and keep a checklist to confirm every step is completed correctly. This approach minimizes risks and keeps your machine running safely.

Conclusion

By keeping these ice cream machine parts in top shape, you’re ensuring your business runs smoothly—no more crying over spilled milk or broken equipment like a ship lost at sea. Regular maintenance and timely replacements are the secret ingredients to consistent quality and customer satisfaction. Don’t wait for a gremlin in the gears; treat your machine like a trusty steed, and it’ll serve you well through many a summer’s day.