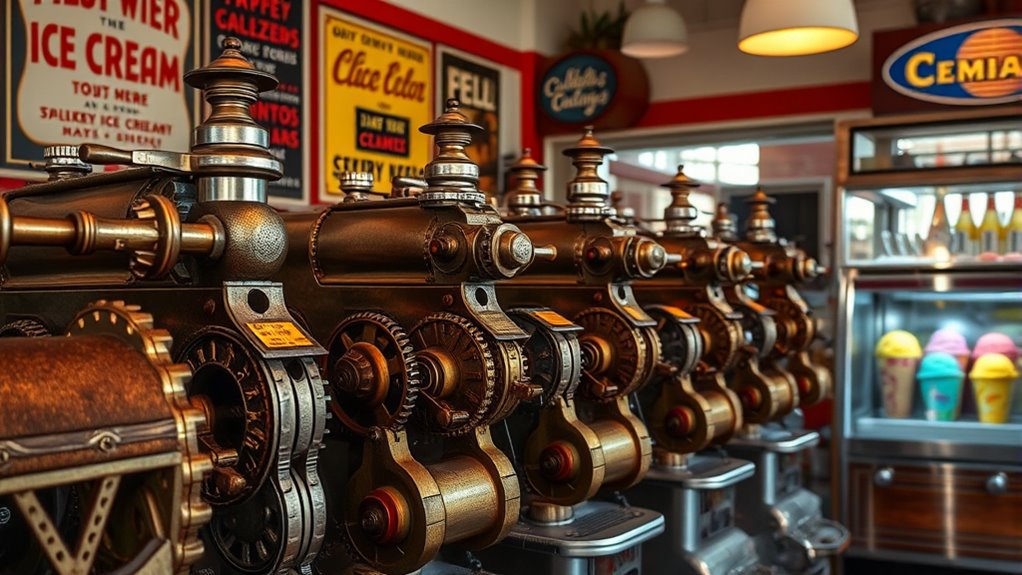

The story of commercial ice cream machines begins with simple hand-cranked devices that revolutionized home production and community sharing. As technology advanced, improvements in refrigeration, gear design, and continuous freezers boosted efficiency, quality, and scale. The invention of the first commercial freezer and electric-powered equipment transformed the industry, enabling faster, larger batches. Today’s high-tech, automated machines push innovation further. Explore how these innovations shaped the industry and continue to evolve into the future.

Key Takeaways

- Early hand-crank machines allowed home ice cream making, fostering community and flavor innovation through manual churning methods.

- Mechanical advancements improved efficiency, insulation, and insulation, supporting larger batches and consistent quality in commercial production.

- The invention of continuous freezers in the 20th century enabled rapid, large-scale freezing, resulting in smoother textures and lower costs.

- Electric refrigeration technology revolutionized industry practices, allowing year-round production and precise temperature control for delicate ingredients.

- Modern automated machines with digital controls and AI integration optimize production, enhance flavor customization, and promote sustainability.

Early Beginnings: The Birth of Ice Cream Making

Long before the advent of modern machines, people experimented with freezing mixtures to make ice cream. Early on, they used simple techniques like placing containers in snow or ice to chill ingredients. As techniques evolved, gelato methods emerged, emphasizing slower churning and lower air content, which enhanced flavor intensity and texture. These gelato techniques allowed for greater flavor innovation, encouraging artisans to explore unique ingredients and infusions. The focus was on balancing creaminess with rich, concentrated flavors, setting the stage for future innovations. Early enthusiasts understood that controlling temperature and stirring was key to creating a smoother, more refined product. Additionally, exfoliating skin before tanning helped ensure an even application and better results. This foundational experimentation laid the groundwork for the development of more sophisticated ice cream-making methods, ultimately leading to the diverse array of flavors and textures we enjoy today. Furthermore, advances in temperature control during freezing significantly improved the consistency and quality of ice cream, paving the way for modern commercial machines. Innovations like controlled freezing processes contributed to achieving uniform textures and efficient production at scale, demonstrating the importance of precise freezing techniques in commercial settings. As technology progressed, the integration of mechanical refrigeration systems further revolutionized ice cream production, allowing for larger-scale manufacturing with consistent results.

Hand-Cranked Machines and Their Innovations

You see, early hand-cranked ice cream machines revolutionized how vendors made frozen treats. Mechanical innovations like improved gears and paddles increased efficiency and consistency. These advancements had a lasting impact, paving the way for more sophisticated production methods. Additionally, the development of precious metals dealer reviews allowed for better selection of reliable suppliers and safeguarding assets. The introduction of dynamic communication exercises for couples also contributed to better teamwork in operating these machines efficiently. Furthermore, the evolution of ethical hacking techniques has played a crucial role in securing the technological advancements used in modern ice cream manufacturing processes. Incorporating technological innovations enabled manufacturers to produce ice cream more safely and at higher volumes.

Early Hand-Crank Designs

Early hand-crank ice cream machines marked a significant step in home dairy innovation, allowing users to produce frozen treats without commercial equipment. These machines harnessed hand crank innovation, making manual operation straightforward and accessible. You would turn the crank steadily, which agitated the mixture and helped it freeze evenly. Early designs often featured a simple, cylindrical container with an inner churning paddle, surrounded by a cooling mixture like ice and salt. The manual operation required effort but gave you control over the freezing process. This innovation made homemade ice cream more practical and fun for families, reducing reliance on expensive or bulky appliances. These early hand-crank designs laid the foundation for further improvements, emphasizing simplicity, affordability, and user involvement. Additionally, the popularity of these machines contributed to the rise of beachside family vacations, where homemade ice cream became a staple treat, and innovations in cooling technology continued to evolve. As the demand for homemade ice cream grew, manufacturers began to experiment with different materials and designs, improving durability and efficiency. These advancements also helped foster a sense of community and shared experience at family gatherings, where making ice cream together became a cherished activity. Furthermore, the introduction of new insulating materials helped maintain colder temperatures for longer periods, enhancing the efficiency of the early devices.

Mechanical Innovations Introduced

Building on the foundation of simple hand-crank designs, inventors focused on enhancing mechanical efficiency and user experience. They developed innovations that improved the consistency and speed of gelato production, allowing for smoother textures and more refined flavors. By refining gear mechanisms and crank systems, these machines required less effort while increasing output. This also opened doors for flavor innovation, as easier operation meant experimenting with new ingredients and techniques. Improved insulation and more precise control over freezing rates helped preserve delicate flavors and textures. These mechanical advancements made ice cream making more reliable and accessible, setting the stage for future technological breakthroughs. Mechanical efficiency played a critical role in elevating ice cream production, making the process more streamlined and user-friendly. Additionally, advancements in insulation technology contributed to maintaining optimal temperatures during the freezing process, further enhancing product quality. Furthermore, innovations in gear mechanism design helped reduce operator fatigue and increased production capacity, making commercial machines more practical for busy environments. Your experience with early hand-crank machines became more efficient, paving the way for sophisticated innovations in commercial ice cream production. Moreover, ongoing improvements in material durability ensured longer-lasting machines capable of withstanding rigorous commercial use, while also supporting hygienic maintenance standards essential in food equipment.

Impact on Ice Cream Production

The introduction of hand-crank ice cream machines revolutionized production by making the process more efficient and accessible. With these innovations, small-scale creators could experiment with flavor innovation, introducing unique and diverse tastes that previously required large equipment. This shift allowed ice cream makers to stand out through creative combinations, appealing to consumer preferences. Additionally, the simplicity of hand-crank machines enabled effective marketing strategies, as vendors could showcase their craft directly to customers, emphasizing freshness and customization. As a result, ice cream became more widely available, boosting sales and expanding the market. The ease of use also encouraged home production, fostering a culture of personalization and innovation that persists today. Moreover, the introduction of flippers and other mechanical components in pinball machines showcased the importance of game mechanics in enhancing player engagement. Overall, hand-crank machines played a *vital* role in shaping modern ice cream production and marketing, with their design simplicity contributing to widespread adoption and ongoing development. Additionally, the accessibility of these machines promoted a craftsmanship mentality that encouraged continual improvement and adaptation in the industry.

The Rise of Mechanical Refrigeration Technology

As technological innovations advanced, mechanical refrigeration emerged as a game-changer for the ice cream industry, transforming how ice cream was produced and stored. This breakthrough allowed for consistent cooling, reducing reliance on natural ice and enabling year-round production. With improved efficiency, manufacturers adopted more sustainable practices, minimizing waste and energy consumption. Mechanical refrigeration also opened doors for flavor innovation, as precise temperature control preserved delicate ingredients and expanded creative possibilities. You can now experiment with unique flavors without worrying about spoilage, leading to a broader variety of options for consumers. This shift not only boosted production capacity but also promoted environmentally conscious methods, helping the industry move toward more sustainable growth. Mechanical refrigeration truly revolutionized ice cream manufacturing, setting the stage for future advancements.

The Invention of the First Commercial Ice Cream Freezer

The invention of the first commercial ice cream freezer revolutionized how ice cream was made and sold. Early freezing techniques relied on hand-cranked or simpler methods, but this device introduced efficiency and consistency. Its patent and industrial impact paved the way for widespread production and the growth of the ice cream industry.

Early Freezing Techniques

Innovations in freezing techniques laid the groundwork for the first commercial ice cream freezers. Early methods relied on simple ice and salt to lower temperatures, making it possible to produce frozen desserts on a larger scale. These techniques improved dairy processing, allowing manufacturers to create smoother, creamier textures. You might imagine how artisans used hand-cranked devices or large salt-and-ice containers to freeze mixtures gradually. While primitive, these methods marked a significant step forward, enabling more consistent results and larger batches. Over time, these innovations paved the way for more sophisticated machinery, transforming ice cream from a luxury into a widely accessible treat. Your understanding of these early freezing techniques highlights how ingenuity and experimentation fueled the evolution of commercial ice cream production.

Patent and Industrial Impact

Have you ever wondered how the first commercial ice cream freezers transformed the industry? Their patents sparked rapid innovation, allowing manufacturers to produce consistent quality and larger quantities. This breakthrough enabled ice cream shops and brands to experiment with new flavors, leading to ice cream flavor innovation that captivated consumers. The industrial impact extended beyond production, as marketing and branding became vital in distinguishing products. Companies leveraged patents to protect their technological advancements, giving them a competitive edge. As a result, the industry experienced a surge in variety and accessibility. These advancements laid the foundation for modern ice cream manufacturing, making the treat a staple across cultures. Today, the legacy of that first freezer continues to influence how brands innovate and market their frozen delights.

Advancements in Freezing Techniques in the 20th Century

As the 20th century unfolded, significant breakthroughs in freezing techniques transformed the production of ice cream. You saw the introduction of continuous freezers, which allowed rapid, large-scale freezing, resulting in smoother textures and improved quality. These advancements enabled manufacturers to experiment with flavor innovations, offering a wider variety of products that appealed to diverse tastes. Marketing strategies also adapted, highlighting new textures and flavors made possible by these techniques, drawing more customers. The development of more efficient freezing methods reduced costs and increased output, making ice cream more accessible. These technological improvements not only enhanced product consistency but also fueled innovation, setting the stage for the modern, ever-expanding ice cream industry you enjoy today.

The Role of Automobiles and Mobile Units in Ice Cream Distribution

Automobiles transformed how ice cream reaches customers, making mobile vendors more popular. Advances in vehicle refrigeration technology keep the product cold during transit, ensuring quality. These mobile units improve route planning and distribution efficiency, expanding access to ice cream everywhere.

Mobile Ice Cream Vendors

The rise of mobile ice cream vendors transformed how you access frozen treats by enabling vendors to bring their products directly to neighborhoods, parks, and busy streets. These vendors often adapt with flavor innovations and eye-catching packaging designs to attract customers. Their mobility allows for quick responses to demand and seasonal trends, keeping offerings fresh and exciting. Many vendors now customize their units with colorful graphics and branding to stand out. This flexibility has expanded options for consumers seeking convenient treats on the go. Here’s a look at some key aspects of mobile vendors:

| Feature | Benefit | Example |

|---|---|---|

| Flavor innovations | Keeps products exciting | Unique seasonal flavors |

| Packaging designs | Attracts attention | Bright, reusable containers |

| Mobile units | Reaches diverse locations | Ice cream trucks, carts |

| Custom branding | Builds recognition | Themed graphics and logos |

| Seasonal operation | Maximizes sales | Summer-only vending |

Vehicle Refrigeration Technology

Mobile ice cream vendors rely heavily on vehicle refrigeration technology to keep their products cold and fresh during transit. Advancements in refrigeration units ensure consistent cooling, allowing vendors to serve high-quality ice cream anywhere. This technology supports the use of sustainable packaging by maintaining ideal temperatures and reducing waste from spoiled products. Additionally, reliable refrigeration fosters flavor innovation, enabling vendors to experiment with new recipes on the go.

Here are four key aspects:

- Compact, energy-efficient cooling systems fit easily into mobile units.

- Temperature controls ensure ice cream remains at the perfect serving temperature.

- Insulation techniques improve efficiency and reduce environmental impact.

- Integration with solar power options promotes sustainability in mobile refrigeration.

These innovations help vendors deliver fresh, delicious ice cream with minimal environmental footprint.

Route and Distribution Efficiency

How do vehicles optimize ice cream distribution to guarantee products arrive fresh and on time? Modern delivery vehicles use route planning technology to minimize transit times and maintain ideal temperatures, ensuring quality. Mobile units equipped with advanced refrigeration keep ice cream at the perfect consistency, supporting flavor innovation by preserving delicate tastes. Sustainable packaging also plays a key role, reducing environmental impact while protecting products during transit. Efficient routes enable you to serve more customers quickly, reducing spoilage and waste. Plus, real-time tracking helps you adjust routes on the fly, avoiding delays. These innovations allow you to deliver ice cream with maximum freshness, supporting both consumer satisfaction and eco-friendly practices—making each scoop a delight from shop to customer.

The Impact of Electric Power on Machine Efficiency and Capacity

As electric power became more reliable and widely available, ice cream machines saw significant improvements in both efficiency and capacity. You benefit from faster production times and larger batch sizes, making operations more profitable. Electric power also enabled the integration of sustainable materials, reducing environmental impact. Additionally, the user interface became more intuitive, simplifying operation and maintenance. Here’s how electric power changed your machines:

- Increased motor strength for higher output

- Enhanced cooling systems for consistent quality

- Integration of programmable controls for precision

- Improved safety features and ease of use

These advancements transformed traditional machinery into more efficient, larger-capacity systems, paving the way for modern commercial ice cream production.

Modern Developments: High-Tech, Automated Ice Cream Machines

Recent advances in technology have revolutionized commercial ice cream machines, making them more intelligent and automated than ever before. These high-tech machines now adapt seamlessly to demand, improving efficiency and consistency. Automation reduces manual labor, allowing you to focus on flavor innovation and customer experience. Modern machines support sustainable packaging options, helping you reduce environmental impact without sacrificing quality. Advanced sensors and digital controls ensure ideal freezing and mixing, creating smoother, more consistent textures. You can also experiment with new flavors effortlessly, thanks to programmable recipes. These innovations empower you to deliver fresh, exciting ice cream options faster and more sustainably, meeting today’s eco-conscious consumers’ expectations while elevating your business’s technological edge.

Key Inventors and Companies Shaping the Industry

Several key inventors and companies have driven the evolution of commercial ice cream machines, shaping the industry’s technological landscape. These innovators introduced innovations that enhanced flavor variety, like artificial flavors, and improved nutritional content, meeting changing consumer demands.

- Dairy Equipment Inc. revolutionized batch freezers, increasing production speed and consistency.

- Walter Van Winkle developed early continuous freezing machines, making large-scale manufacturing feasible.

- Hanson Industries pioneered advanced refrigeration systems, improving energy efficiency and product quality.

- Nostalgia Ice Cream Co. integrated flavor customization options, including artificial flavors, to cater to diverse tastes.

These companies and inventors played vital roles in shaping the industry’s technological landscape, influencing how commercial ice cream meets consumers’ flavor and nutritional expectations.

The Future of Commercial Ice Cream Technology

Advancements driven by pioneering companies and inventors have set the stage for exciting innovations in commercial ice cream technology. Artificial intelligence is now playing a key role in optimizing production processes, ensuring consistency, and reducing waste. You can expect machines that automatically adjust recipes based on customer preferences or ingredient availability, enhancing flavor innovation. Future equipment will likely incorporate smart sensors to monitor temperature, texture, and freshness in real-time. This technology enables you to create unique, customized flavors at an unprecedented scale, meeting diverse consumer demands. As automation advances, you’ll see faster, more efficient machines that maintain high quality and hygiene standards. Overall, these innovations promise a new era where ice cream production is smarter, more flexible, and endlessly inventive.

Frequently Asked Questions

How Did Early Ice Cream Machines Influence Social Gatherings Historically?

Early ice cream machines transformed social event evolution by making frozen treats more accessible and fun. You’d gather friends around these machines, turning simple gatherings into communal dining trends. They encouraged shared experiences, fostering conversations and bonding over homemade or machine-made ice cream. This innovation not only changed how people celebrated but also helped establish traditions of communal enjoyment, shaping social interactions during parties and special occasions.

What Materials Were Initially Used in Constructing the Earliest Commercial Ice Cream Machines?

Imagine the earliest commercial ice cream machines as rough-hewn sculptures, crafted with primal materials. You’d find early materials like wood and metal used in construction techniques that prioritized durability and practicality. The wooden frames provided sturdy foundations, while metal components, such as copper or brass, enabled efficient cooling. These materials, though simple, laid the groundwork for the sophisticated machines we enjoy today, blending ingenuity with raw resourcefulness.

How Did Regulations and Safety Standards Evolve With Ice Cream Machine Technology?

You see, as ice cream machine technology advanced, regulations and safety standards evolved to prioritize food safety and regulatory compliance. You’re now required to follow strict hygiene practices, use FDA-approved materials, and guarantee proper maintenance to prevent contamination. These standards help protect consumers and maintain quality, so you can confidently serve ice cream knowing that safety protocols are in place. This ongoing evolution keeps the industry safe and trustworthy for everyone.

What Role Did Patent Disputes Play in the Development of Commercial Ice Cream Equipment?

Did you know that patent battles once delayed ice cream machine innovations by over a decade? These disputes over rights often caused significant innovation delays, hindering progress in commercial equipment. When inventors fiercely protected their designs, it slowed down the development and widespread adoption of better machines. So, patent disputes played a vital role in shaping the pace and direction of ice cream technology, sometimes stalling progress for years.

How Have Global Markets Affected Innovations in Ice Cream Machine Design?

Market globalization has driven innovation in ice cream machine design by encouraging manufacturers to develop more efficient, versatile equipment to meet diverse international tastes. You see, as supply chains become more complex, companies focus on creating machines that are easier to maintain and adapt across different regions. This global demand pushes technological advancements, ensuring you get better, faster, and more reliable ice cream machines no matter where you are.

Conclusion

So, after all this, it’s ironic that despite every high-tech gadget and automated marvel, the heart of ice cream still comes down to a simple desire for a cold treat. You’ve seen how centuries of innovation have paved the way for today’s machines, yet sometimes, all you really want is that perfect scoop—no fancy tech needed. Maybe the future’s greatest breakthrough will be realizing that sometimes, old-school charm beats all the bells and whistles.